Product Details

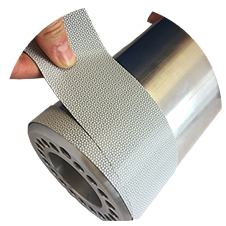

JemmTrac™ Rubberized Cork Traction Tape features a durable, high coefficient of friction surface that offers excellent gripping characteristics and prevents moving webs from wandering, while keeping rollers turning, without causing wrinkles or sticking points.

Jemmco's JemmTrac™ Rubberized Cork Traction Tape is easy to apply to rollers, and is commonly used on web guides, slitters and other converting equipment. The tape is a combination of cork and a rubber co-polymer and has a high performance acrylic adhesive that provides good adhesion to metals and most other roller surfaces.

Note: Limited Stock Available on Some Sizes. Call 262-512-9559 for larger quantities.

Features

- Available in standard wall thicknesses of 1/32”, 1/16” and 1/8” rolls

- 2" wide rolls are in stock

- Custom widths available upon request

Please call for a quote for the following items: 1" x 1/32", 1"x 1/32" CB, 1" x 1/16", 1" x 1/16" CB, 1" x 1/8", 1" x 1/8" CB, 2" x 1/32", 2" x 1/32" CB, 3" x 1/32", 3" x 1/32" CB, 3" x 1/16", 3" x 1/16" CB, 3" x 1/8" and 3" x 1/8" CB. Items listed may require quantity minimum and lead time.

Technical Specifications

| Release Properties |

Poor |

| Traction Properties |

Good |

| Heat Resistance |

-20°F to 200°F |

| Wear Resistance |

Excellent |

| Hardness |

50-70 Shore A |

| Adhesive Type |

Acrylic |

| Surface Finish |

Cork |

| Wall Thickness |

1/32" (+/- .015"), 1/16" (+/- .020"), 1/8" (+/- .020") |

| Available Widths |

1", 2", 3" |

| Available Lengths |

50 ft, 100 ft |

| Liner |

No |

| FDA Compliant |

No |

Technical Data

| Adhesion to steel |

Good |

| UV Resistance |

Excellent |

| Optimal Application Temperature |

45°F to 80°F |

| Service Temperature |

-20°F to 200°F |

| Water and Humidity Resistance |

Excellent |

Installation

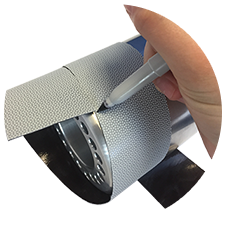

Four Simple Steps for In-Plant Tape Installation!

- 1.

To get started, wrap your Jemmco tape one full rotation around the roller at the angle required to achieve your spiral. Make a mark on the second wrap where it meets the beginning of the tape.

- 2.

Lay the tape on a flat cutting surface and cut the tape at an angle from the marked point to the opposite corner of the beginning of the tape roll.

- 3.

If applicable, remove the liner at the start point and begin wrapping the tape at the edge of the roller.

- 4.

Wrap the tape around the roller - at even angles - without leaving any gaps or air underneath the tape.